You may be struggling to keep machines and equipment in working order so that they are accurate and safe for your employees to use. With many different types of equipment with differing calibration schedules or safety inspections, it quickly becomes a full time job to manage it all. You can alleviate this by implementing preventative maintenance software.

Preventative maintenance software gives you one place to track your past, present and future work orders. Depending on the software you may be able to schedule both predictive maintenance and preventive maintenance. This takes the stress off of you and your technicians and allows the software to handle scheduling for you. In the post, we are going to cover:

- Reasons to schedule asset maintenance

- What are The Benefits of Using Software to Schedule Asset Maintenance?

- How do you Know When Preventive Maintenance Software is Needed?

1. Reasons to Schedule Asset Maintenance

One of the keys to high productivity is ensuring your machines are running at peak performance, 100% of the time. Properly maintaining your machines directly results in higher productivity. Your machines will constantly be running at their peak and proper maintenance means extended longevity of these machines. Most manufactures offer warranties with the main caveat being that proper maintenance is performed.

Another benefit to proper maintenance is the overall safety of these machines. Routine maintenance puts you in control of your assets situation. When routing maintenance is forgotten at some point that machine will reach its breaking point, which will lead to an unexpected and uncontrolled situation. This is where injuries come from.

2. Benefits of Using Software to Schedule Asset Maintenance

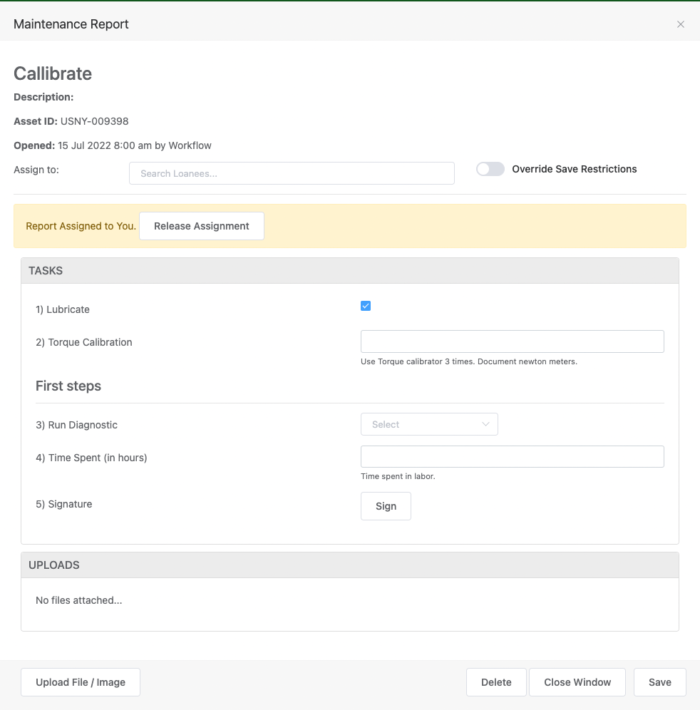

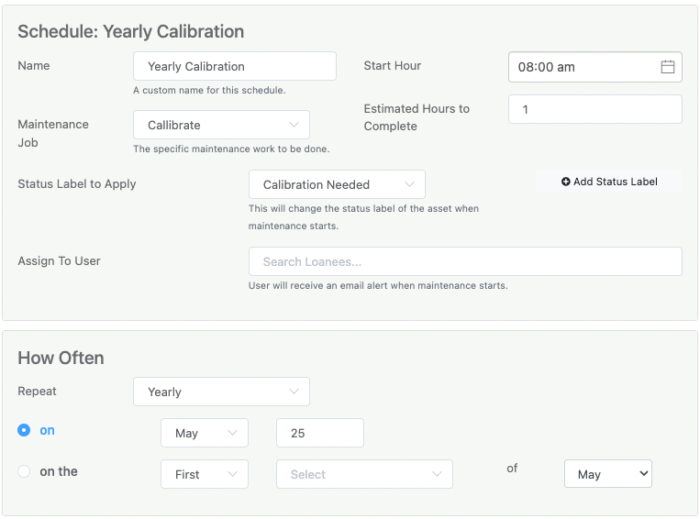

It’s entirely possible to track all of this maintenance on a spreadsheet, however, you will need extensive knowledge in order to create a proper schedule. When using spreadsheets for asset maintenance, your work orders, your schedule and your notes are generally held in three separate places. Proper maintenance software puts all of this information in one place. You and your technicians should have easy access to all asset maintenance. This means at any point in time, your technicians should be able to refer back to past maintenance orders. This can help ensure firstly that all tasks were done but what exactly were the results of each test. Rather than keeping a clipboard attached to the asset, this can easily be completed on a smart device. Lastly, asset maintenance software helps improve accountability within your organization. Maintenance orders can automatically be assigned to your technicians. Once they have completed this maintenance, their manager can be notified and even reminded if maintenance has yet to be completed.

3. How do you know when Preventative Maintenance Software is needed?

As mentioned above, it’s entirely possible to complete this with a spreadsheet. However, once that spreadsheet is out of control it may be too late. Being in the asset management industry, we have had the chance to speak with numerous clients on this exact topic. They told us, spreadsheets were great in the beginning. After a few months they realized these same spreadsheets just weren’t cutting it. Our clients were feeling overwhelmed and almost completely unable to keep up. They began searching for a fix to this problem and found Reftab to be the answer. Reftab is able to consolidate all of your assets, their maintenance (past, present and future) and the employees these are assigned to in one place. If you have multiple assets in need of maintenance there is no better time than now. The best course is to create an action plan before there is a problem. When you get into the specs of any machine, there is a defined lifespan. Being able to track this lifespan along with all maintenance performed can greatly increase both safety and performance in your workplace.

Conclusion

You can see how important proper maintenance on your machines is. Implementing a proper maintenance procedure could seem like a daunting task but we’re here with you every step of the way. We recommend scheduling a demo with us. We will talk about your exact maintenance needs and help you implement proper plans and procedures to complete this maintenance.