Warehouse management is about solving this fundamental problem. That’s how to keep track of a lot of stuff—tools, inventory, equipment—and make sure it’s all in the right place at the right time. Sounds simple, but anyone who’s managed warehouse operations knows it’s anything but.

Without the right systems, warehouses become a black hole. Tools go missing. Inventory counts are wrong. Warehouse managers waste time running in circles. The bigger the operation, the bigger the chaos. And that chaos costs money in the form of higher labor costs, more storage space, frequent delays, and lower customer satisfaction.

The answer is rarely more people or more warehouse space. Instead, it’s a better way to manage what’s already there. That’s where a warehouse management solution—and the systems that support it—come in.

In this post, we’re sharing how warehouse management works and how it can help you tame the chaos.

What is warehouse management?

Warehouse management is about having the right systems in place to make sure everything—from tools to equipment to inventory—is exactly where it needs to be, when it needs to be there. It’s about keeping your inventory management and supply chain management processes tight to ensure operational efficiency and meet customer demands effectively. Whether you’re managing a single site or multiple warehouses, these systems are what keep everything running smoothly.

For teams in Ops and IT, an efficient approach to warehouse management means less chaos and improved customer service. Tools are easy to find, maintenance is up to date, and you’re not wasting time searching for that one missing item that throws off the whole day. Proper warehouse management also supports demand forecasting and timely deliveries. This ensures you’re prepared to respond quickly and keep customers happy.

What is a warehouse management system (WMS)?

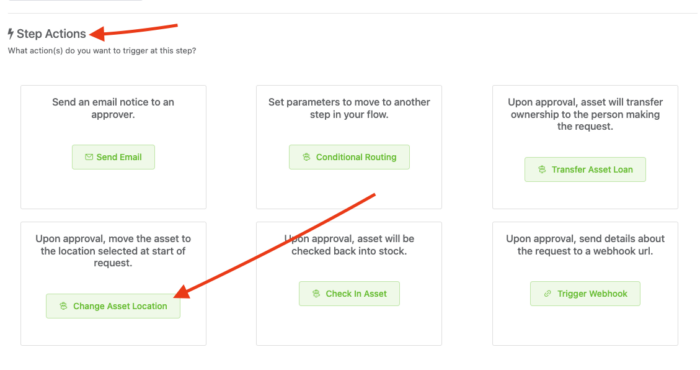

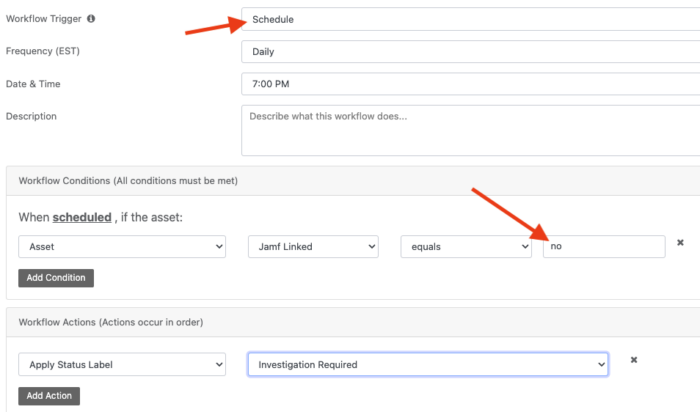

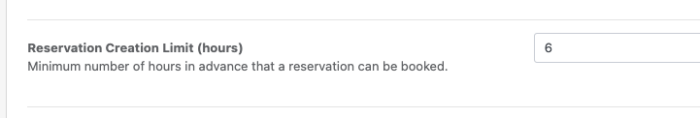

A Warehouse Management System (WMS) is what turns warehouse chaos into something you can actually manage. It’s warehouse management software designed to keep track of everything from a customizable request portal for equipment check-ins and check-outs to maintenance management—so nothing falls through the cracks. A good WMS streamlines the warehouse management process, making it easier for both warehouse staff and management to keep everything in order.

With the right WMS, you spend less time hunting things down and more time focusing on warehouse efficiency and logistics management. No more messy spreadsheets or trying to remember which shelf that one tool got tossed onto. The right WMS ensures that your warehouse runs smoothly, keeps your team on track, and improves overall operational efficiency.

Inventory management vs warehouse management: What’s the difference?

Inventory management and warehouse management might sound like the same thing, but they’re not. Inventory management is all about the “what.” It’s focused on the raw materials, products, and spare parts themselves and tracks how much stock you have, what’s running low, and when you need to reorder.

On the other hand, warehouse management is the “how.” It’s about how you store, move, and manage everything inside the warehouse. It’s making sure the right stuff is in the right place at the right time.

Or, put another way, inventory management helps you understand what you have (and maintain optimal inventory levels). Warehouse management makes sure you can actually find it, move it, and keep it organized.

Benefits of warehouse management

Simply put, effective warehouse management makes everything easier.

- Better organization. You know where everything is, and nothing gets lost. No more wasted time searching for that one tool or part.

- Improved efficiency. When things are organized, the whole operation moves faster. Less downtime and less confusion. Your team gets what they need without the hassle.

- Real-time visibility. You get a clear picture of what’s in stock, what’s out, and what’s on the move. No guesswork—just the info you need when you need it.

- Reduced costs. Fewer mistakes, less waste. You’re not overstocking or running out of important items. Better management means smarter decisions, and that saves money.

- Proactive maintenance. Keeping track of tools and equipment gets a whole lot easier. You’ll know what needs maintenance and when so nothing falls apart when you need it most.

- Happier team. A well-managed warehouse is less stressful for everyone. It’s easier to find what they need and get the job done.

Top warehouse management processes

Warehouse management is all about having well-defined processes that keep things moving smoothly. In a modern warehouse, every step—when done well—helps cut operational costs, improve inventory accuracy, and enhance the customer experience.

These are the key processes that every warehouse needs to master.

- Receiving – This is where it all starts. Receiving is about ensuring real-time inventory tracking and that what’s coming in matches what’s expected. Checking quantities, inspecting for damage, and logging items accurately are essential parts of this process. Any hiccup here can ripple through other warehouse processes and lead to inaccurate stock counts or delays that impact customer experience. For example, a smart asset tracking system that immediately scans and logs incoming items can make the entire downstream process more efficient.

- Putaway – Once items are received, they need to be put in the right place to maximize storage capacity. Items should be easy to find and retrieve, without taking up valuable space that could be used for higher turnover items. Reducing the time it takes to move products from receiving to storage minimizes manual processes and boosts overall warehouse efficiency.

- Storage – Storage is about optimizing warehouse space and ensuring easy access. High-turnover items need to be within easy reach in your storage locations, while less frequently used inventory can go further back. This makes the picking process faster and more efficient.

- Picking – Picking is about getting the right items ready to fulfill an order. This step is crucial because the faster and more accurately you can pick, the fewer mistakes you’ll have down the line. Batch picking, for example, can be highly effective for products with high demand, cutting down on repeated trips across the warehouse and reducing operational costs.

- Packing – Once items are picked, packing is the next step. Modern warehouses might use automated packing solutions to streamline this process. Good packing practices not only help maintain inventory accuracy but also contribute to a positive customer experience by ensuring items arrive safely and correctly.

- Shipping – Shipping is all about getting the order out the door and into the hands of the customer. Timely deliveries are critical to maintaining a strong customer experience. Mistakes in labeling or incorrect shipment timing can lead to higher shipping costs, costly returns, and unhappy customers. Using logistics management tools can help ensure every order is properly labeled, tracked, and reaches its destination on time.

- Returns – Returns are part of the game, but a smooth returns process makes all the difference. Handling returns efficiently allows you to get items back into inventory quickly or decide if something needs repair or disposal. Effective return management helps maintain inventory accuracy and ensures product demand is met without unnecessary delays. How well you manage returns impacts your operational costs and the overall customer experience.

Each of these steps plays a crucial role in keeping the warehouse efficient. Nail each one, and you’ve got a warehouse that works like a well-oiled machine.

Why do you need a warehouse management system?

A warehouse management system is what keeps your warehouse running smoothly instead of descending into chaos. Without one, you’re stuck with spreadsheets, sticky notes, and a lot of guesswork. That means more mistakes, wasted time, and frustrated team members in your day to day operations.

With a WMS, you’ll know what’s where, what’s running low, and what needs attention. It keeps everything organized on the warehouse floor, cuts down on errors, and makes your job easier.

But not every WMS is built the same, so picking the right one matters. Here’s what to look for:

- Scalability. Choose a WMS that can grow with your needs. You might only have one small warehouse right now, but you want something that can handle more complexity as you expand.

- Ease of use. If it takes weeks to learn, your team won’t use it properly. Look for something intuitive and easy to train on.

- Integration. A WMS should fit with what you’re already using. Whether that’s accounting software, sales CRMs, or enterprise resource planning software (ERPs), the WMS needs to connect easily without giving you extra headaches.

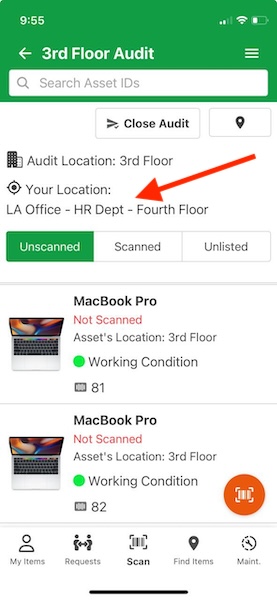

- Real-time inventory tracking. The point of a WMS is to always know what’s happening. Real-time updates mean fewer surprises and less scrambling when things go off track.

- Mobile compatibility. Warehouses aren’t just desks and computers. Find a WMS that works with mobile devices, so your team can check or update info wherever they are, without running back to a terminal.

- Support and training. Even the best systems need help now and then. Make sure the WMS provider has a strong support team and training resources, so you’re covered if something goes wrong.

When you’re choosing a WMS, focus on what will make your warehouse more efficient and take the pain out of everyday operations.

Best practices for improving your warehouse management

Here are some additional ways to improve your warehouse.

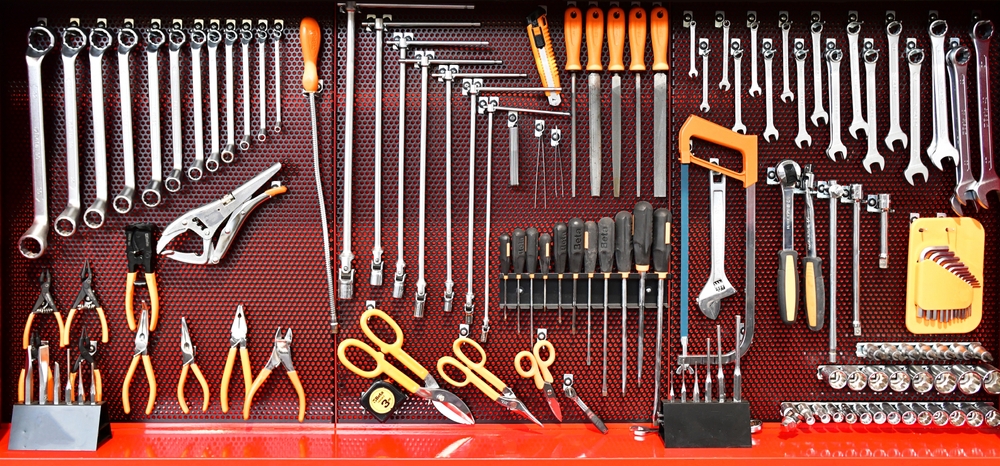

- Organize your layout. Make sure everything has a logical place. High-use items should be easy to access, and there should be clear paths for moving around. A good layout is key to keeping things efficient.

- Label everything. Labels make all the difference. Whether it’s shelves, bins, or tools, clear labeling helps your team find what they need without wasting time.

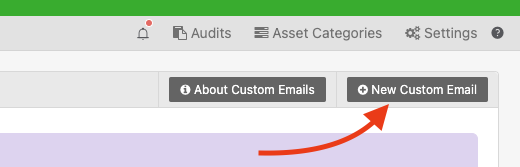

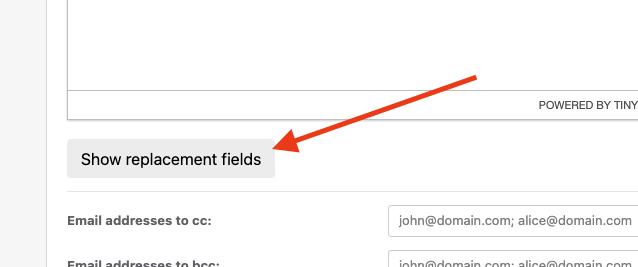

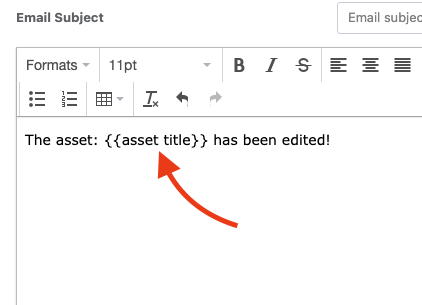

- Use a WMS. From real-time inventory updates to tracking tools and equipment, the right software can transform how your warehouses and job sites operate.

- Prioritize safety. Safety should always come first. Make sure aisles are clear, shelves are stable, and everyone knows the protocols. A safe warehouse is an efficient warehouse.

- Train your team. Warehouse management is only as good as the people running it. Regular training keeps everyone on the same page, and it helps them work smarter, not harder.

- Adopt regular maintenance routines. Don’t let small issues turn into big problems. Regular maintenance keeps your equipment working and helps avoid unexpected downtime.

- Keep an eye on performance. Use metrics to track how well your warehouse is running. From order accuracy to picking speed, measuring performance helps you spot problems and find opportunities to improve.

Wrap-up

Warehouse management is all about tackling the core challenge: keeping everything—inventory, tools, equipment—where it should be, when it’s needed. Without the right processes, it’s easy for things to spiral out of control. Items get lost, time gets wasted, and costs pile up.

But it doesn’t have to be that way. A solid Warehouse Management System (WMS) can turn your warehouse from a source of constant headaches into a well-oiled machine. It streamlines the chaos, provides real-time visibility, and helps your team work smarter, not harder.

If you are looking for an asset tracking solution that will save you time and money, Reftab offers easy-to-use solutions for inventory management, asset tracking, and even self-serve check-in and check-out tools for your team. With Reftab, you’ll always know where your equipment is, who’s using it, and when maintenance is due—all in real time. No more lost items, no more wasted time, and no more guesswork. Get started with a free account.